Warehouse Sustainability: Why It Matters

Now more than ever, there’s a growing call to action for organizations to focus on environmental and social standards. These standards don’t just keep the world around us cleaner and greener, but it also helps to improve a business’ profits by improving efficiency, productivity, and its reputation for having a responsible business model.

While much of the focus is on transportation when it comes to creating a sustainable supply chain, that’s not where the biggest impact is made : “Buildings account for almost 40 percent of global energy-related CO2 and will play a major role in a sustainable transformation.” Whether it’s a new warehouse project or a renovation, there are several considerations to keep in mind to make it sustainable.

All About Location

The location of a warehouse is the foundation of a supply chain’s sustainability initiatives. Last-mile delivery improvements and the eCommerce boom have pushed warehouses and distribution centers into more urban centers. Being closer to ports, airports and highways mean a shorter distance for inventory to travel. It also helps employees more easily get to and from work, which cuts down carbon emissions.

Having a warehouse located in more developed urban areas also taps into existing infrastructure. Even when green strategies and sustainable materials are used, building out additional infrastructure (like utilities or plumbing) can detrimentally impact the environment.

Take It Inside

The good news is that there’s no shortage of tools and best practices that facility managers can leverage to make the interior of a warehouse more sustainable.

Construction materials: Use green insulation, avoid paint with chemicals, use naturally-occurring wood products — all of this will increase energy efficiency and improve indoor air quality.

Sensors: These are key for resource management, helping to automate warehouse systems like lighting, HVAC, and even equipment, turning it off when appropriate to save energy.

LED lighting: In warehouses, lighting takes up the majority of electricity. LED upgrades can be implemented in existing buildings as well as added to new construction design.

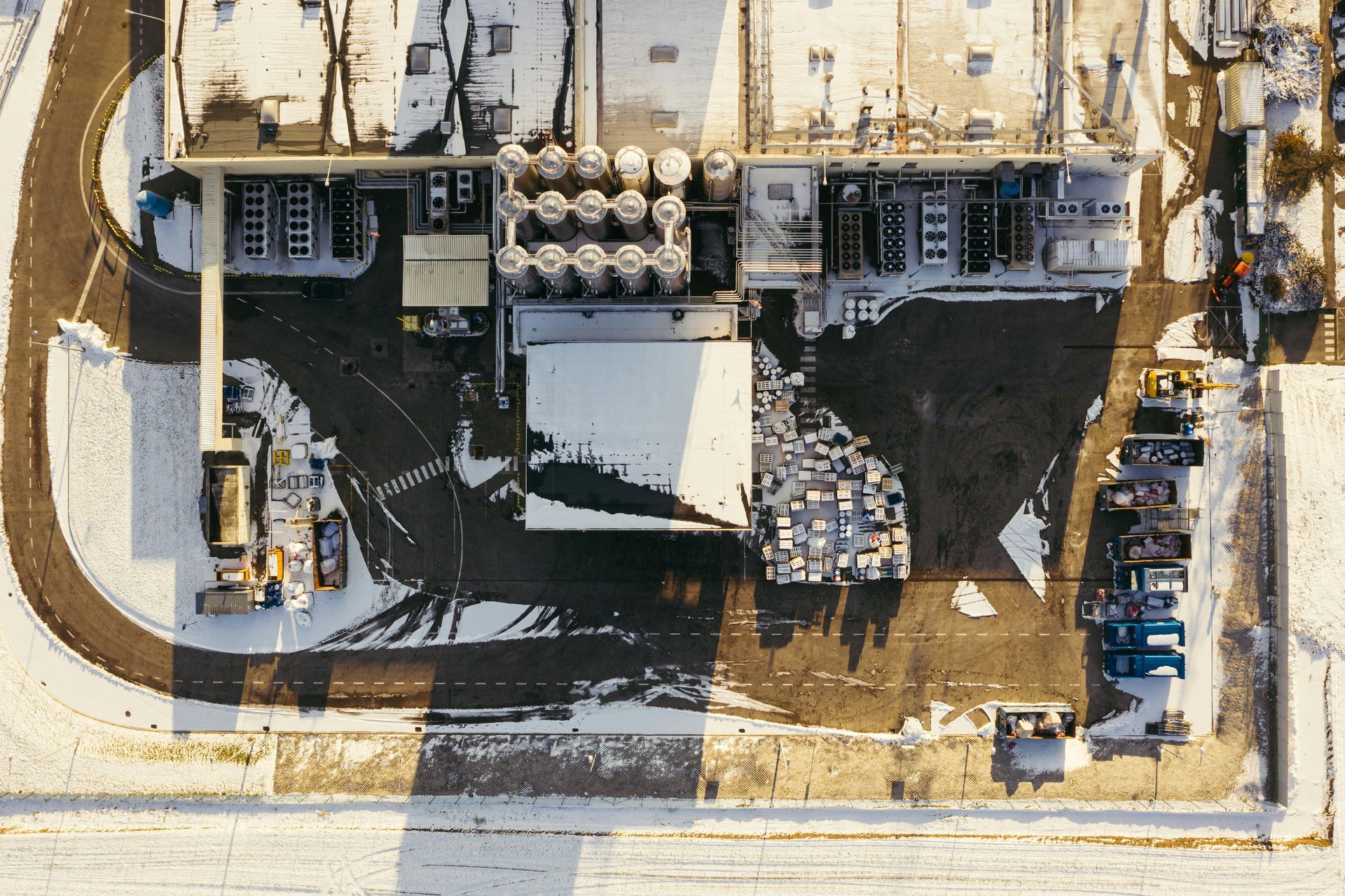

On the Exterior

It can be easy to think that all of the sustainability measures should be leveraged on the interior of a warehouse, but there are additional steps to take on the outside. Cool roofs are helping to keep energy costs down, and smarter landscaping with optimal water utilization can reduce use — especially in drought-prone areas. Solar power panels help supplement traditional power sources and reduce the electrical load. Warehouse loading dock doors and other entrances can be upgraded to close and open strategically, limiting exposure to the elements that could impact HVAC performance.

Other Ways to Stay Sustainable

Even the smallest moves can make a big difference when it comes to warehouse sustainability.

Build up instead of out: Expanding your warehouse footprint doesn’t have to mean adding more square footage. Add shelving vertically to utilize space that’s above heads.

Add some fans: Large fans inside your warehouse help distribute the air more consistently, allowing HVAC systems to work smarter and not harder.

Invest in tech: Warehouse management systems and other tech tools can help give managers a look at real-time data that helps drive warehouse sustainability forward.

Upgrade equipment: This falls under the tech umbrella. Innovations mean that equipment like forklifts can be autonomously managed and efficiently charged.

Recycle and reuse : When looking for vendors for warehouse supplies, find those who practice recycling and reuse, and implement recycling policies for warehouse employees.

Staying on Track

To fully understand how sustainable a warehouse can be, organizations must set goals and identify the metrics and milestones. Why does an organization decide to focus on sustainability? Is it to make a public statement? Or is it truly a goal to bring operations closer to net-zero (when a building generates energy equal to or less than they use)? Answering these questions will give warehouse managers, stakeholders, and leaders a clear idea if efforts are working.

Talk to the Pros

Once goals have been established and warehouse sustainability strategies have been employed, the next logical step is to partner with pros that have experience helping organizations with creating greener warehouses. Whether you’re looking for equipment for your newly purchased warehouse or you’re looking to replace aging warehouse supplies, Benco Industrial Equipment can help.

We also provide MacroAir fans, warehouse doors and docks, warehouse racks & racking, and we respond in minutes, not days, to assure our customers always have the material handling equipment they need to keep their warehouses running smoothly. Our staff is experienced in handling all sorts of industrial equipment issues, from forklift repair to installing new warehouse doors. Let’s work together to make your warehouse more sustainable.

The post Warehouse Sustainability: Why It Matters appeared first on Benco Industrial Equipment.