Fundamentals of Forklift Safety

Fundamentals of Forklift Safety. It doesn’t matter if you’ve been working on a forklift for years or if this is your first week on the job; it’s always helpful to have safety reminders when it comes to using this piece of equipment in the warehouse.

We consulted with safety experts, industry veterans, and existing safety guidelines to offer basic safety best practices that you may or may not be using. Remember — a forklift is nothing like a car and doesn’t function like a personal vehicle, so don’t drive it like it does!

Training

Forklifts can weigh up to 9,000 pounds, travel up to 18 mph, and only have brakes in the front, which makes them much harder to stop than a car. Nearly 62,000 forklift accidents are reported every year, with about half of those resulting in serious injury; 70% of those accidents could be prevented. These are just a few stats that highlight the importance of proper and thorough training for forklift operators.

An untrained forklift driver can be just as dangerous as someone who drives a car without a license. Although OSHA requires formal training to be combined with on-the-job experience, this education isn’t comprehensive or universal. Every forklift brand and model is a bit different, and training on one doesn’t mean operators are prepared for every type of forklift.

Inspection

Forklift operators should inspect equipment before each and every use, full stop. There should also be a protocol in place, usually in the form of a checklist that’s followed each time. This gives operators an opportunity to ensure that safety features (like seatbelts) are working properly, the tires are properly inflated, and there are no mechanical issues that could cause an accident.

Failing to perform regular inspections doesn’t just increase the chance of an accident, it can also be costly to pay non-compliance fines. Not inspecting your equipment can also increase maintenance costs; repairs can become extensive or even lead to total replacement when small issues are left to grow into major problems. Let’s not even mention what can happen to warehouse operations and productivity if a piece of machinery is taken off the floor.

Machinery

This may sound like a no-brainer, but there’s little that’s more important to safe forklift operation than knowing the equipment and safety rules for using it.

- Keep a clear view

- Always look in the direction of travel

- Use spotters or aids such as rear-view mirrors to boost visibility

- Use headlights if working at night, outdoors or in areas in which additional lighting would improve visibility

- Use the seatbelt every time — it can prevent serious injury in the event of a rollover

- Be aware of your surroundings, especially if a load or environment may cause visibility obstructions

- Make eye contact with pedestrians to ensure that they are aware of the equipment’s path

Stability

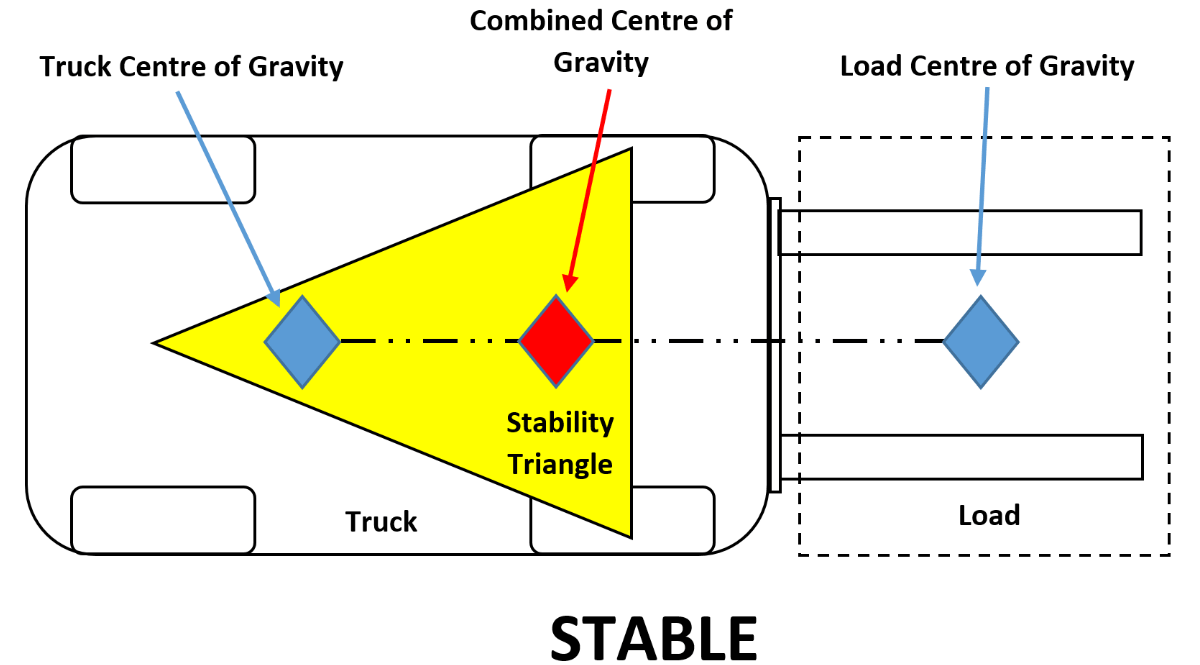

Forklifts have a high center of gravity, and with a load, that center of gravity is combined. Three-point suspension on lifts put support at both ends of the front axle and one in the middle of the back axle. Operators must stay within this “stability triangle” to help keep the forklift upright. Several factors can disrupt this triangle, including imbalanced or too-heavy loads and unsafe driving. These tips can help:

- Stabilize and secure loads before operating a forklift

- Keep loads low to the ground while using the forklift

- Make sure loads are uphill when going up or down an incline

- Go slowly during wet or slippery conditions to avoid tipping

- Take it easy around turns and don’t be shy about using the horn

Loads

How operators handle loads can go a long way towards supporting a culture of forklift safety. According to OSHA, some required recommendations and requirements include securing the load, centering it as much as possible, and avoiding overload. For a more comprehensive explanation, check out the agency’s website for a refresher. It’s a great read, and it covers a long list of forklift safety best practices when it comes to loading, carrying, and unloading objects.

Above all, safety starts with properly using and maint aining high-quality equipment. Whether you’re looking for equipment for your newly purchased warehouse or you’re looking to replace aging warehouse supplies, Benco Industrial Equipment can help. We are the best source for forklift service, repair, sales, and leasing in St. Louis, St. Charles, Jefferson County, and the surrounding areas! We are dedicated to providing the critical sales, service and repair you need to keep your warehouse running smoothly — get in touch!

The post Fundamentals of Forklift Safety appeared first on Benco Industrial Equipment.